Advanced Press Technology: A Comprehensive Guide to Servo Presses and Comparison with Mechanical Presses

- Emrah Demirezen

- Jul 12, 2025

- 27 min read

Metalforming presses are indispensable tools in modern manufacturing, serving as the backbone for shaping metals through processes such as stamping, punching, bending, and drawing. These machines are critical for producing a vast array of components across diverse industries, including automotive, aerospace, electronics, and consumer goods. Historically, mechanical presses, relying on flywheels and crankshafts, were the dominant technology, offering robust force delivery and high-speed operation. The evolution of press technology saw the introduction of hydraulic presses, which provided enhanced control over applied force. The advent of servo technology marks a significant leap, representing what is widely recognized as the "third-generation" punch press. This advanced technology integrates sophisticated control and unparalleled flexibility to address the complex demands and efficiency imperatives of contemporary manufacturing.

Detailed Guide to Servo Presses

Servo presses embody a revolutionary approach to metalforming, offering precision and adaptability previously unattainable with conventional press technologies. Their operational principles are rooted in advanced electromechanical systems, providing granular control over every aspect of the pressing cycle.

Principles and Operation: How Servo Presses Work

The core principle behind a servo press involves utilizing a servomotor as the direct power source. This motor converts its rotary motion into the linear motion of the ram, enabling precise, programmable control over the ram's position, velocity, and applied force throughout the entire stroke. This differs fundamentally from traditional presses, which operate with fixed stroke characteristics.

A key capability of servo presses is their ability to execute programmable motion profiles. Operators can define specific parameters for force, speed, and dwell time, meticulously tailoring the stroke to the exact requirements of a given application. This inherent flexibility allows for optimal processing of various stamping operations and is particularly advantageous when working with difficult-to-form materials. This adaptability signifies a profound shift from a fixed manufacturing process to a highly customized, recipe-based approach for each part. This enables the formation of challenging materials and complex geometries with greater ease and superior quality, opening new possibilities for product design. The ability to perform more work in fewer die stations directly results from this adaptive control, leading to reduced tooling costs and simplified production lines.

The system operates on a sophisticated closed-loop control mechanism. High-precision sensors, including load cells and encoders, provide real-time feedback on the ram's position, speed, and the force being applied to the controller. The controller, acting as the system's "brain," continuously processes this data and adjusts the servomotor's output to precisely maintain the programmed profile. This continuous feedback loop is critical for ensuring high accuracy, repeatability, and overall process stability.

The operation of a servo press follows a sequence of precisely coordinated events:

Programming the Motion Profile: The operator defines the stroke parameters, including force, speed, and dwell time, typically using a Human-Machine Interface (HMI) or a Programmable Logic Controller (PLC).

Initiating the Press Cycle: Once the program is set, the control system transmits commands to the servomotor, initiating the ram's movement.

Ram Movement and Control: The servomotor precisely controls the ram's acceleration, velocity, and deceleration. The system constantly adjusts speed and force based on the real-time feedback received from its array of sensors.

Force Application and Monitoring: The servo press applies force with exceptional accuracy, maintaining consistent pressure throughout the stroke. Load cells continuously monitor the applied force, ensuring precision and repeatability.

Dwell or Secondary Operations: A distinct advantage of servo presses is their capacity to hold the ram at any position during the stroke. This enables the execution of in-die operations such as tapping, riveting, or controlled material flow, which are not feasible with conventional presses.

Ram Retraction and Reset: Upon completion of the operation, the ram smoothly and efficiently retracts to its home position, preparing for the subsequent cycle.

Key Components: In-depth Description

A servo press system relies on a suite of interconnected, high-precision components to achieve its advanced capabilities:

Servomotor: This is the central power source of the system. Typically an AC synchronous, brushless motor, it is selected for its high torque-to-inertia ratio, which allows for rapid acceleration and deceleration. The servomotor provides precise control over position, velocity, and torque.

Ballscrew (or Roller Screw) Mechanism: This mechanism is responsible for converting the rotary motion of the servomotor into the linear motion of the press ram. Ballscrews are commonly employed due to their high efficiency, low friction, and precision. For applications requiring higher load capacity and stiffness, roller screws are often preferred.

Crank-Slider Mechanism: Some servo presses utilize a crank mechanism to convert the rotary motion of the servomotor (the crank) into the reciprocating (back-and-forth) motion of the ram (the slider). This design allows for reversible travel direction, with one full rotation of the crank moving the slider both upward and downward. This type of mechanism is particularly effective at delivering maximum force precisely at the mechanical bottom dead center of the ram's stroke.

Load Cell: Integrated into the press mechanism, often directly on the ram or within the tooling, the load cell is a force transducer that measures the applied force in real time. These are typically strain gauge-based and are crucial for providing force feedback and ensuring the correct force profile is maintained throughout the operation.

Encoder: A rotary encoder is attached to the servomotor shaft, and sometimes a linear encoder is used directly on the ram. These encoders provide precise feedback on the ram's position and speed, which is essential for the closed-loop control system to function accurately.

Controller: Often referred to as the "brain" of the system, the controller can be a dedicated motion controller or a Programmable Logic Controller (PLC) equipped with motion control capabilities. It receives programmed instructions, processes feedback from the load cell and encoder, and sends precise commands to the servo amplifier.

Servo Amplifier (Drive): This electronic component receives commands from the controller and precisely regulates the power supplied to the servomotor, thereby controlling its speed, torque, and position.

Human-Machine Interface (HMI): A control panel or touchscreen interface that allows operators to program the press, monitor its operation, and view critical process data.

Holding Brake & Timing Belt: These components ensure stability and precision in positioning, particularly during dwell periods when the ram needs to be held stationary.

Table 1: Servo Press Key Components and Functions

Component Name | Description/Function |

Servomotor | Primary power source; AC synchronous, brushless motor for precise control of position, velocity, and torque; high torque-to-inertia ratio for rapid acceleration/deceleration. |

Ballscrew (or Roller Screw) Mechanism | Converts servomotor's rotary motion into linear motion of the ram; high efficiency, low friction, precision (ballscrews); higher load capacity, stiffness (roller screws). |

Load Cell | Force transducer (strain gauge-based) measuring applied force in real time; crucial for force feedback and maintaining correct force profile. |

Encoder | Rotary encoder on servomotor shaft (and/or linear encoder on ram); provides precise feedback on ram position and speed for closed-loop control. |

Controller | The "brain" (motion controller or PLC); processes programmed instructions and sensor feedback, sends commands to servo amplifier. |

Servo Amplifier (Drive) | Electronic component regulating power to servomotor based on controller commands, controlling speed, torque, and position. |

Human-Machine Interface (HMI) | Control panel/touchscreen for programming, monitoring, and data visualization. |

Holding Brake & Timing Belt | Ensures stability and precision in positioning during dwell periods. |

Ballscrew vs. Crank-Slider Mechanisms in Servo Presses

While both ballscrew and crank-slider mechanisms are employed in servo presses to convert the motor's rotary motion into the ram's linear motion, they offer distinct advantages:

Table 2: Ballscrew vs. Crank-Slider Mechanisms in Servo Presses

Feature | Ballscrew (Direct-Drive) Servo Press | Crank-Slider Servo Press |

Motion Conversion | Converts rotary motion directly to linear (up/down) motion of the ram using a screw and nut system. | Converts rotary motion of a crank into reciprocating (back-and-forth) motion of a slider (ram). |

Ram Position Control | Offers free ram position control, allowing for highly flexible processing. | Exerts maximum thrust at the mechanical bottom dead center under the ram. |

Flexibility | Highly flexible for various motion profiles and precise control throughout the stroke. | Well-suited for applications requiring high force at the very end of the stroke. |

Energy Efficiency | Generally high energy efficiency, contributing to lower CO₂ emissions. | Can be designed to reduce required servomotor power (e.g., less than 40% of direct drive type) through linkage mechanisms for energy saving. |

Hydraulic Oil | Does not require hydraulic oil, making it suitable for clean room environments. | May or may not utilize hydraulic oil depending on the overall press design; the crank mechanism itself is mechanical. |

Impact & Noise | Can be configured to lower ram speeds when approaching the workpiece, thereby reducing impact and noise. | Dynamically changing inertia, thrust, and gravity effects necessitate careful consideration in design. |

Maintenance | Features fewer components compared to hydraulic/mechanical systems, generally requiring low maintenance over time. | Mechanical components (crank, connecting rod) may require specific maintenance considerations. |

Operational Advantages and Capabilities

Servo presses offer a compelling array of operational advantages that significantly enhance metalforming processes:

Precision and Control (Force, Stroke, Speed): Servo presses provide unparalleled control over the force applied during each stroke, as well as precise adjustments to stroke length and speed. This capability is critical for operations such as forming, blanking, and stamping, ensuring consistent results and tight tolerances. The control accuracy can achieve a remarkable 1.6% of the maximum output force. This fine-tuned control allows for a reduction in the touching speed of the tool to a workpiece, which extends tool life and mitigates high impact loads.

Energy Efficiency and Environmental Benefits: A significant advantage of servo presses is their superior energy efficiency. Unlike traditional hydraulic presses that use continuous motors to pump fluid, or mechanical presses that constantly maintain flywheel speed, servo presses consume energy only when the motor is actively engaged ("on-demand"). This leads to substantial energy savings, often ranging from 30% to 60% compared to mechanical presses and 20% to 50% compared to hydraulic counterparts. Furthermore, excess energy generated during non-working portions of the stroke can be stored in capacitors and regenerated, minimizing power consumption during idle periods. These efficiencies translate directly into lower operating costs and reduced peak electrical load, benefiting both the environment and a business's bottom line.

Enhanced Productivity and Flexibility: Servo presses are highly efficient in terms of production speed. Their programmable stroke and speed capabilities allow for rapid movement in non-forming portions of the stroke, while enabling slow, controlled movement during the actual forming process. This optimizes overall production efficiency. The ability to change the direction of rotation at predefined angles, known as "pendulum mode" (e.g., limiting rotation to 90-270 degrees instead of a full 360 degrees), can significantly increase production rates by reducing non-working stroke time. This dynamic control allows for more work to be performed in fewer die stations, reducing tool-build and maintenance costs and potentially eliminating the need for secondary processes outside the press. The versatility of adjustable force, stroke, and speed makes servo presses ideal for a wide range of applications, from simple stamping to complex deep drawing, fine blanking, and embossing, thereby minimizing retooling requirements. Moreover, servo presses can mimic the actions of traditional hydraulic and mechanical presses, making them excellent choices for tool tryout and research and development (R&D), which can reduce final tryout time at customer sites.

Reduced Noise and Vibration: The precise control over the servomotor's movements results in exceptionally smooth operation, significantly reducing noise (by up to 10 decibels) and vibration compared to mechanical or hydraulic presses. This reduction in noise and vibration creates a safer and more comfortable working environment for employees and, crucially, extends the service life of the die by mitigating the impact of the sliding block during sheet metal forming.

Reduced Tool Wear and Maintenance: By applying only the exact amount of force needed for a specific operation, servo presses minimize wear and tear on tooling. This leads to lower maintenance costs and a substantially longer lifespan for both the press machine and its tooling, with reported improvements of as much as three to four times longer tool life. The absence of components like flywheels, clutches, and hydraulic systems (in servo-electric designs) further simplifies the mechanical structure and reduces the number of maintenance points.

Applications: Servo presses are broadly utilized across various metalforming operations, including drawing, punching, bending, cold forging, stamping, and tryout punches. Their precise control capabilities make them particularly well-suited for forming large covers made from high-strength steel, aluminum alloy sheets, magnesium alloys, and titanium alloys. They excel in deep drawing applications, especially for complex shapes, and are effective for blanking, piercing, forming, and shallow drawing, particularly for small to medium-sized parts.

The engineering sophistication of servo presses, characterized by their closed-loop control and advanced motors, directly translates into tangible economic benefits. It is not merely about producing better parts; it is about achieving a holistic improvement in manufacturing economics. This includes lower operational costs, higher throughput, and reduced waste, all of which contribute to making the higher initial investment more justifiable over the long term.

Servo Press Selection Guide

Choosing the appropriate servo press for a production environment is a critical decision that requires a thorough evaluation of various factors. A systematic approach ensures that the selected machine aligns perfectly with operational needs and long-term strategic objectives.

Understanding Production Requirements

The first step in the selection process involves a comprehensive assessment of specific production needs:

Material Type and Thickness: The types of materials to be processed (e.g., high-strength steel, aluminum, magnesium, titanium alloys) and their thicknesses directly influence the required force and control capabilities of the press. Different servo presses are optimized for specific material properties and applications.

Production Volume: The anticipated production volume dictates the necessary speed and throughput of the servo press. High-volume production lines will require presses with faster cycle times and higher capacity to meet demand efficiently.

Application Specifics: A clear identification of the exact operations to be performed—such as stamping, forming, punching, assembly, deep drawing, fine blanking, or embossing—is crucial. This dictates the required force, stroke length, and the degree of control flexibility needed from the press.

Evaluating Performance Characteristics

Once production requirements are clear, the focus shifts to the performance attributes of potential servo presses:

Force and Speed Capabilities: It is essential to assess the maximum force and speed that a servo press can deliver to ensure they align with the demands of the application. More demanding applications or challenging materials will necessitate higher force and speed capabilities.

Accuracy and Precision: A critical factor is the press's ability to provide precise control over stroke, position, and force. This is paramount for achieving consistent and accurate results, especially in applications requiring tight tolerances and stringent quality standards.

Engineering Calculation Considerations: For a detailed engineering evaluation, several parameters must be rigorously checked:

Load Inertia: The load inertia should be less than or equal to the motor rotor inertia multiplied by the applicable inertia ratio, ideally with a margin of approximately 20%.

Effective Torque: The effective torque required for the operation must be less than the motor's rated torque, again, with an advisable margin of about 20%.

Maximum Momentary Torque: The maximum momentary torque demanded by the application must be less than the motor's maximum momentary torque. This value should consider the combined capabilities of the motor and its associated driver, also with a recommended 20% margin.

Maximum Rotation Speed: The maximum rotation speed required should be less than or equal to the motor's rated rotation speed. Striving to operate as close as possible to the motor's rated rotations can enhance efficiency.

Regenerative Energy: It is important to ensure that the regenerative energy generated during deceleration or reversal is less than the motor's absorption capacity. If the regenerative energy is substantial, connecting a regenerative energy absorption resistance may be necessary to increase the driver's absorption capacity.

Encoder Resolution: The encoder resolution must meet the system's specified requirements for positioning accuracy.

Positioner Characteristics: The pulse frequency should not exceed the maximum response frequency or maximum command frequency of the positioner.

Flexibility and Programmability: The press's ability to adapt to different production scenarios is a significant advantage. This includes assessing its programmability, tooling compatibility, and ease of changing motion profiles to accommodate varied jobs.

Safety Features and Compliance

Safety is paramount in any manufacturing environment. Prioritizing servo presses with robust safety features is non-negotiable:

Emergency Stop Functionality: The press must be equipped with easily accessible emergency stop buttons and safety interlocks to quickly halt operations in an emergency.

Light Curtains and Guards: The presence of light curtains, safety guards, and physical barriers is crucial to prevent unauthorized access to hazardous areas during press operations.

Safety Certification: Verification that the servo press meets relevant safety standards and regulations, such as OSHA, is essential for compliance and operator protection.

Redundancy: Features like encoders located at both the motor and the crankshaft provide redundancy, helping to guard against unintended motion that could compromise part quality or damage tooling and press components.

Maintenance and Support Considerations

Long-term reliability and operational efficiency are heavily influenced by maintenance and support:

Maintenance Requirements: Understanding the servo press's maintenance requirements, including lubrication schedules, component replacement intervals, and troubleshooting procedures, is vital for planning and budgeting.

Availability of Spare Parts: Ensuring that spare parts and components are readily available for the servo press is crucial to minimize downtime during repairs or replacements.

Technical Support and Training: Selecting a supplier that offers comprehensive technical support, robust training programs, and thorough documentation is critical. This support assists with installation, operation, and ongoing maintenance. It is worth noting that DSF servo motors, for instance, have a life expectancy that can exceed 25 years, requiring only minimal maintenance such as replacing blower fans and air filters over their lifespan.

Total Cost of Ownership (TCO) Analysis

While the initial purchase price is a significant factor, it is imperative to consider the total cost of ownership (TCO) over the entire lifespan of the servo press. This comprehensive view provides a more accurate financial picture:

Initial Investment: Evaluate the servo press's initial purchase price, including any additional costs for accessories, tooling, and installation. Servo presses typically have a higher initial acquisition cost compared to conventional presses.

Operating Costs: Consider ongoing operating costs such as energy consumption, maintenance, and spare parts replacement over the press's lifetime. Servo presses offer substantial energy savings, with reported reductions in peak load ranging from 30% to 70%.

ROI and Productivity Gains: Assess the potential return on investment (ROI) based on productivity gains (which can be up to 50% higher in continuous mode), improvements in part quality, and reduced scrap rates.

For a manufacturing operation, the decision to invest in a servo press is a strategic one, not merely a capital expenditure. The initial sticker price, though higher, is often offset by substantial long-term operational savings in energy, material, tooling, and maintenance, coupled with increased revenue from higher quality output and greater throughput. This means that a short-sighted focus on initial cost savings could inadvertently lead to significantly higher operational costs and reduced competitiveness over the equipment's lifespan. The return on investment is not just a financial metric; it is a measure of sustained competitive advantage.

Control and Automation Features

Modern servo presses integrate advanced control and automation features that enhance their capabilities:

Consider features such as programmable cams, variable speed drives, variable profile motion, hydraulic overloads, and automatic counterbalancing.

The ability to seamlessly integrate with conventional and robotic loading systems is also a key factor for automated production lines.

The concept of "flexibility" in servo press selection extends beyond the machine's technical specifications. While a servo press offers inherent programmability, tooling compatibility, and adaptability to various production scenarios, its full potential can only be realized if the human operators and engineers are also adaptable and committed to continuous learning. The emphasis on "continuous training" and the role of a "servo champion" underscores that a servo press is not a "set-it-and-forget-it" investment. Its maximum return on investment is unlocked through ongoing human capital investment and a commitment to continuous process improvement. Companies that neglect investment in training and dedicated personnel risk underutilizing the press's capabilities, potentially diminishing the benefits that justify its higher initial cost. This elevates the selection criteria to include organizational readiness and a long-term commitment to technological mastery.

Table 3: Servo Press Selection Criteria Checklist

Category | Specific Criterion | Key Considerations/Questions |

Production Requirements | Material Type & Thickness | What materials will be processed? What are their thicknesses? (e.g., high-strength steel, aluminum, magnesium, titanium alloys) |

Production Volume | What is the required speed and throughput for your production volume? | |

Application Specifics | What operations will be performed (stamping, forming, punching, assembly, deep drawing, fine blanking, embossing)? | |

Performance Characteristics | Force and Speed Capabilities | What are the maximum force and speed required for your applications and materials? |

Accuracy and Precision | Does the press offer precise control over stroke, position, and force for tight tolerances? | |

Flexibility & Programmability | How adaptable is the press to different scenarios (tooling compatibility, ease of motion profile changes)? | |

Safety Features & Compliance | Emergency Stop Functionality | Are emergency stop buttons and safety interlocks present and easily accessible? |

Light Curtains and Guards | Are physical and optical barriers in place to prevent access to hazardous areas? | |

Safety Certification | Does the press meet relevant safety standards and regulations (e.g., OSHA)? | |

Redundancy | Are redundant systems (e.g., encoders) in place to prevent unintended motion? | |

Maintenance & Support | Maintenance Requirements | What are the lubrication schedules, component replacements, and troubleshooting procedures? |

Availability of Spare Parts | Are spare parts readily available to minimize downtime? | |

Technical Support & Training | Does the supplier offer comprehensive support and training for installation, operation, and maintenance? | |

Total Cost of Ownership (TCO) | Initial Investment | What is the purchase price, including accessories, tooling, and installation? |

Operating Costs | What are the projected energy consumption, maintenance, and spare parts costs over the press's lifetime? | |

ROI & Productivity Gains | What is the potential return from increased productivity, quality improvements, and reduced scrap? | |

Control & Automation Features | Advanced Control Features | Does it include programmable cams, variable speed drives, variable profile motion, hydraulic overloads, automatic counterbalancing? |

Integration Capabilities | Can it seamlessly interface with conventional and robotic loading systems? |

Servo Press vs. Mechanical Press: A Comprehensive Comparison

The choice between a servo press and a mechanical press involves a detailed understanding of their fundamental differences, operational characteristics, and strategic implications. Each press type offers distinct advantages suited to different manufacturing contexts.

Overview of Mechanical Presses

Mechanical presses are traditional workhorses in metalforming, relying on a robust mechanical system to generate and apply force.

Principle: A mechanical press operates by converting the rotational motion of a motor into the linear motion of a ram. This is achieved through a mechanical mechanism that builds up kinetic energy, typically in a flywheel, and then releases it to perform the forming operation.

Components: Key components include the motor, a flywheel that accumulates and stores kinetic energy, a drive transmission system (such as screws, crank connecting rods, or toggle levers) that transfers this energy, and the ram which applies the force to the workpiece. A clutch engages the crankshaft, which in turn links the flywheel's power to the ram.

Operation: The process begins with the motor activating the flywheel, allowing it to build up kinetic energy. Once a predetermined energy level is reached, the flywheel releases its stored energy through the drive transmission, driving the ram down onto the workpiece. After the ram completes its stroke, it retracts, and the motor and flywheel begin the process of rebuilding energy for the next cycle.

Drive Transmissions: Mechanical presses are differentiated by their drive transmission types, which influence their force and speed characteristics:

Flywheel Drive: Used for operations like piercing, blanking, bending, and shallow drawing. These presses typically range from 30 to 600 tons and operate at high speeds (125 to 1000 strokes per minute) with very short stroke lengths (around two inches).

Single Geared: The most common type, with tonnage ranging from 200 to 1600 tons. The gear ratio allows the flywheel to run faster, making them suitable for stamping, piercing, and blanking.

Double Geared: Ideal for heavy-duty applications requiring slower stroke speeds (28 strokes per minute or less). The gear ratio allows the flywheel to maintain its speed while the press runs slower, delivering exceptionally high energy. These are often used for deeper draw work where significant energy is required over a longer distance.

Eccentric Geared: Similar to double geared presses but designed for longer strokes (over 24 inches). They offer greater accuracy due to refined clearance arrangements of the gear train and slide guiding gib adjustment.

Action Classification: Mechanical presses can also be classified by the number of rams or slides they possess:

Single Action: Features a single slide or ram, holding one die at a time to perform a single operation in a single stroke.

Double Action: Equipped with two rams, one positioned inside the other. The outer slide holds the workpiece firmly in place, while the inner slide performs the shaping operation.

Multiple Action: Designed to perform several metal shaping operations concurrently, such as drawing, forming, shaping, and cutting. One ram typically serves as a clamping mechanism, while others shape the workpiece.

Engineering-Level Specifications Comparison

A detailed engineering comparison reveals the fundamental operational differences between servo and mechanical presses.

Motion Control and Stroke Profiles:

Mechanical Press: Characterized by unidirectional and constant-speed shaft rotation during production. The slide speed is fixed, peaking near the midway point of the stroke and slowing to zero at top dead center (TDC) and bottom dead center (BDC). Operators cannot fine-tune the slide speed for specific forming operations.

Servo Press: Offers unparalleled flexibility in motion. The shaft can accelerate and decelerate as needed for the application, and critically, it can change rotational direction. This allows for precise fine-tuning of the speed at impact or during forming, while still maintaining high overall production rates. A significant advantage is the ability to operate in "pendulum mode," where the press changes its direction of rotation at predefined angles (e.g., limiting rotation between 90 and 270 degrees instead of a full 360 degrees). This dramatically increases the production rate by reducing the non-working portion of the stroke. The non-constant rotation of the shaft in a servo press, however, can lead to increased fatigue due to reversing torsional stresses and requires overcoming inertia and static friction more frequently, which also alters lubrication conditions.

Tonnage Control and Curves (ATC, PTC, DoB):

Mechanical Press: The available tonnage curve (ATC) is directly related to the torque available within the system and generally remains constant with shaft speed throughout the operational range. The maximum tonnage capacity (PTC) is achieved at a specific rated distance off bottom (DoB).

Servo Press: The available tonnage is also linked to motor torque. However, the ATC of a servo press scales down as the shaft speed exceeds its rated speed. This phenomenon occurs because the available torque in servo motors decreases above their rated speed, which also leads to a decreased rated DoB. Despite this, for applications requiring full tonnage, the shaft speed can be intentionally reduced during the forming portion of the stroke to ensure maximum force is available, while increasing speed during the non-forming portion to maintain a high production rate. It is important to note that while servo presses offer programmability, their fundamental tonnage curve is similar to mechanical presses due to their underlying mechanical drivetrain (eccentric gear or shaft).

Torque Delivery and Energy Management:

Mechanical Press: Relies on a flywheel to store and deliver kinetic energy, and a clutch mechanism to engage and limit torque to the shaft.

Servo Press: The servomotor directly delivers the required torque to the shaft, either through gears or a direct drive system. The absence of a flywheel and clutch not only reduces the number of components but also helps to lower overall system inertia. Servo presses incorporate advanced energy management systems that store excess energy, often in capacitors, for later use.

Component Complexity and System Inertia:

Mechanical Press: Features a complex array of mechanical components, including a flywheel, clutch, crankshaft, and various linkages (e.g., pitmans). The flywheel contributes significantly to higher system inertia.

Servo Press: Generally has fewer mechanical components, as it eliminates the need for a flywheel and clutch. It primarily uses electro-mechanical actuators (such as ball or roller screws) coupled with servo motors and drives. This design results in lower system inertia.

Synchronization and Control System Differences:

Mechanical Press: Synchronization of inputs and outputs (e.g., programmable limit switches, die protection, tonnage monitor windows, auxiliary outputs) is relatively straightforward. This is because the angular position of the shaft increases consecutively from 0 to 360 degrees, occurring only once within a single stroke.

Servo Press: Due to its inherent motion flexibility, including variable speeds and pendulum mode operation, a given angular position of the shaft may repeat multiple times within a single stroke. This necessitates a more complex synchronization process, often employing a "virtual angle" to track the motion profile's progress relative to completing a stroke, ensuring precise coordination with auxiliary equipment. The "virtual angle" is a sophisticated control mechanism that unlocks the full potential of programmable motion. It allows the press to maintain consistent timing and synchronization for auxiliary equipment (feeds, transfers, die protection) even when the physical shaft motion is highly dynamic and non-linear. This is crucial for achieving the high production rates and complex in-die operations that define servo press superiority, signifying a deeper level of computational control that transcends simple mechanical linkage and enables complex automation and integration previously unattainable.

Operational and Performance Comparison

Beyond engineering specifications, operational performance highlights the practical distinctions.

Precision, Part Quality, and Tolerances:

Mechanical Press: The fixed stroke characteristics can limit precision, potentially leading to higher impact forces and a greater likelihood of defects.

Servo Press: Offers exceptional accuracy and repeatability due to precise control over force and stroke. This results in tighter tolerances, reduced waste, minimal defects, and consistently improved product quality.

Energy Consumption and Efficiency:

Mechanical Press: Consumes energy continuously to maintain flywheel speed, leading to lower efficiency, especially during the non-working portions of the stroke.

Servo Press: Operates on an "energy-on-demand" principle, consuming power only when the motor is active. Its regenerative energy storage capabilities further enhance efficiency, leading to significant energy savings, typically ranging from 20% to 70%.

Noise and Vibration Levels:

Mechanical Press: Higher impact speeds inherent in their operation can lead to increased vibration and noise, with motors and pumps often exceeding 90 decibels.

Servo Press: Achieves smoother operation due to precise control over motor movements, resulting in significantly lower noise levels (up to 30% quieter, with a reduction of up to 10 decibels) and reduced vibration.

Tool Wear and Life Expectancy:

Mechanical Press: High impact loads and fixed operating speeds can contribute to greater tool wear and a shorter overall tool life.

Servo Press: Reduces impact loads through controlled punch velocity and optimized slide motion. This significantly extends tool life, often by three to four times, leading to substantial cost savings and reduced downtime.

Production Speed and Cycle Times:

Mechanical Press: Can achieve high strokes per minute for simple, repetitive operations. However, the overall cycle time can be limited by the fixed stroke profile and the inability to optimize non-forming portions of the cycle.

Servo Press: Capable of achieving significantly higher overall productivity (up to 50% higher in continuous mode) by optimizing stroke speed—moving rapidly through non-working portions and slowly during forming—and leveraging pendulum mode. This also reduces downtime between strokes.

Versatility and Application Range:

Mechanical Press: Best suited for high-speed, repetitive operations such as blanking and piercing, where consistent stroke requirements are paramount. They offer less flexibility for varied materials or complex geometries.

Servo Press: Highly versatile due to its programmable force, stroke, and speed capabilities. It is ideal for a wide range of applications, including deep drawing, fine blanking, embossing, and forming difficult materials. A single servo press can emulate the motion profiles of various conventional press configurations, offering greater adaptability.

Management Overview and Strategic Implications

From a management perspective, the decision between servo and mechanical presses involves a strategic evaluation of costs, productivity, and long-term operational advantages.

Initial Acquisition Cost vs. Long-Term ROI:

Mechanical Press: Typically represents a lower initial investment, making it an attractive option for businesses with limited capital budgets or straightforward production needs.

Servo Press: Commands a higher initial acquisition cost. However, this higher upfront investment is justifiable through a substantial return on investment (ROI) derived from increased productivity, reduced scrap, lower operational costs, and extended tool life.

Operational Costs (Energy, Maintenance, Scrap, Downtime):

Mechanical Press: Generally incurs higher energy consumption and potentially higher maintenance costs due to the wear and tear on mechanical components like clutches and flywheels.

Servo Press: Offers substantial energy savings, ranging from 30% to 70% reduction in peak load. It also leads to reduced scrap rates (potentially 2% to 10% cost reduction) and decreased factory downtime. While maintenance on mechanical components is reduced due to fewer moving parts, the complexity shifts to electronics, requiring different maintenance expertise. The claim that servo presses are "easier to maintain" often refers to the reduced frequency of heavy mechanical overhauls, but it necessitates a re-skilling of the workforce, which is a critical human resource and operational planning consideration for companies transitioning to servo technology.

Productivity Gains and Setup Time Reduction:

Mechanical Press: Productivity gains are largely limited to raw strokes per minute, as the fixed stroke profile offers little room for optimization beyond that. Setup times can be considerable.

Servo Press: Provides a significant reduction in setup time. Its ability to optimize cycle times through variable speed and pendulum mode leads to a notable increase in parts produced per shift or per day, further aided by fewer stoppages due to misfeeds or nuisance faults.

Material Cost Savings and Die Station Consolidation:

Mechanical Press: Less flexible in handling materials with a wide range of mechanical properties, potentially leading to higher material waste.

Servo Press: Can form quality parts from materials with a broader allowable range of mechanical properties, contributing to material cost reduction. Its versatility allows for combining die stations, eliminating restrike stations, and integrating secondary operations (such as in-die tapping) directly into the die, thereby streamlining production processes.

Maintenance Requirements and Life Expectancy of Key Components:

Mechanical Press: Requires regular maintenance on its mechanical drivetrain components, including the clutch, flywheel, and crankshaft.

Servo Press: Features fewer mechanical components like the flywheel and clutch, which simplifies maintenance. However, the presence of energy management systems introduces more electrical components, requiring different maintenance expertise. Servo motors themselves boast a long life expectancy, often exceeding 25 years with minimal maintenance (e.g., replacing blower fans and air filters).

Importance of Training and "Servo Champion" Role:

Mechanical Press: Operation is relatively straightforward once the press is set up, requiring less specialized ongoing training.

Servo Press: To maximize its ROI, continuous and ongoing application training for engineers, programmers, and operators is crucial. Appointing a "servo champion"—a dedicated engineer focused on developing and testing new servo press production programs—is vital for continuous improvement and leveraging the technology's full potential. This commitment to human resource development ensures that the initial investment in a servo press continues to yield benefits throughout its operational life.

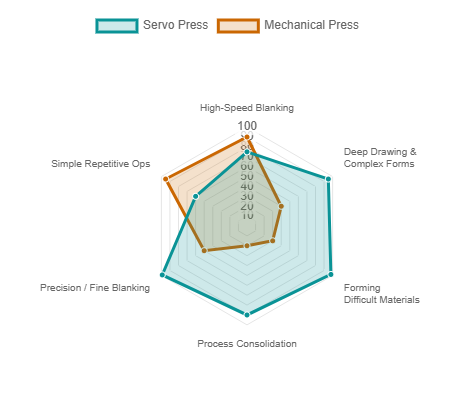

Application Suitability

The optimal choice between a servo press and a mechanical press heavily depends on the specific application requirements.

Optimal applications for Servo Presses:

Applications demanding full energy and tonnage at relatively low speeds, such as deep drawing or cold forging.

Forming difficult-to-form materials like high-strength steel, aluminum, magnesium, and titanium alloys.

Producing complex shapes and parts that require tight tolerances and high precision.

Operations involving multi-operation dies or the consolidation of die stations.

Applications where reducing vibration, reverse tonnage, or impact load is critical.

Situations requiring a wide range of stroke lengths or specialized motion profiles.

Processes that benefit from improved synchronization with transfer and feed systems.

High-energy consumption applications, where their energy storage capabilities provide an advantage.

Use as tryout equipment for tooling, capable of mimicking various press actions.

Optimal applications for Mechanical Presses:

Manufacturing operations seeking a lower initial capital investment.

High-speed blanking and piercing operations with relatively low energy requirements.

Production of similar and relatively simple parts with consistent stroke requirements.

Applications that require full torque at maximum speeds.

The decision to invest in a servo press is a commitment to future-proofing and enhancing competitive advantage. While mechanical presses offer a lower barrier to entry, they may limit a company's ability to adapt to new materials, complex designs, or higher quality demands. Servo presses, despite the higher initial outlay, provide the agility and precision necessary to tackle more challenging, higher-value projects, reduce operational waste, and potentially open up new market opportunities. The choice is less about immediate cost and more about long-term strategic positioning in a dynamic manufacturing landscape.

Table 4: Comprehensive Comparison: Servo Press vs. Mechanical Press

Category | Mechanical Press Characteristics | Servo Press Characteristics | Key Differences/Advantages |

Principle | Relies on mechanical mechanism (flywheel, crankshaft) to build and release kinetic energy for linear ram motion. | Utilizes servomotor as direct power source, converting rotary motion to linear ram motion with precise control. | Servo offers direct, programmable control; Mechanical relies on fixed kinetic energy release. |

Motion Control & Stroke Profiles | Unidirectional, constant shaft speed; fixed slide speed, fastest midway, slows at TDC/BDC; cannot fine-tune speed. | Flexible, variable speed/direction; fine-tune speed at impact/forming; "pendulum mode" for higher rates. | Servo allows dynamic optimization of stroke; Mechanical is fixed. |

Tonnage Control & Curves | ATC generally constant with shaft speed; PTC at rated DoB. | ATC scales down above rated speed due to decreased motor torque; DoB also decreases. | Servo can deliver full tonnage at low speeds; Mechanical best at max speeds. |

Torque Delivery & Energy Mgmt. | Flywheel delivers torque; clutch limits it; kinetic energy storage. | Servomotor directly delivers torque; no flywheel/clutch; energy management stores excess in capacitors. | Servo's direct drive reduces components; efficient energy storage. |

Component Complexity & Inertia | Flywheel, clutch, crankshaft, complex linkages; higher system inertia. | Fewer mechanical components (no flywheel/clutch); electro-mechanical actuators; lower system inertia. | Servo has simpler mechanical structure, but more electrical complexity. |

Synchronization | Simple coordination with single angular shaft position (0-360 deg). | Complex synchronization due to variable motion (virtual angle needed for repeated real angles). | Servo requires advanced control for dynamic motion. |

Precision & Part Quality | Fixed stroke limits precision; higher impact, potential for defects. | High accuracy/repeatability; tighter tolerances, less waste, minimal defects. | Servo offers superior part quality and consistency. |

Energy Consumption | Consumes energy continuously to maintain flywheel speed; less efficient. | Energy-on-demand; regenerative energy storage; 20-70% energy savings. | Servo is significantly more energy efficient. |

Noise & Vibration Levels | Higher impact speeds lead to increased noise (90+ dB) and vibration. | Smoother operation, significantly lower noise (30% lower, up to 10 dB reduction) and vibration. | Servo provides a quieter, safer work environment. |

Tool Wear & Life Expectancy | High impact loads, fixed speeds lead to greater tool wear, shorter life. | Reduced impact loads, controlled punch velocity, extended tool life (3-4x longer). | Servo dramatically extends tooling lifespan. |

Production Speed & Cycle Times | High SPM for simple ops; overall cycle limited by fixed stroke. | Higher overall productivity (up to 50% higher) by optimizing stroke speed, pendulum mode; reduced downtime. | Servo offers higher net productivity and throughput. |

Versatility & Application Range | Best for high-speed, repetitive blanking/piercing; less flexible. | Highly versatile; programmable force/stroke/speed; ideal for deep drawing, difficult materials. | Servo handles wider range of complex applications. |

Initial Acquisition Cost | Lower upfront investment. | Higher initial acquisition cost. | Servo requires higher initial capital outlay. |

Long-Term ROI | Lower initial cost, but potentially higher operational costs. | Higher initial cost, but strong ROI from energy savings, reduced scrap, extended tool life, productivity gains. | Servo provides superior long-term financial benefits. |

Maintenance Expertise | Traditional mechanical maintenance skills. | Shifts to electrical and software expertise; requires re-skilling. | Servo requires different, often more specialized, maintenance skill sets. |

Human Capital Investment | Less critical for ongoing optimization. | Crucial for maximizing ROI; requires continuous training and dedicated "servo champions." | Servo demands ongoing investment in human resources. |

Reputable Servo Press Manufacturers

The market for servo presses is diverse and global, featuring a range of manufacturers from established industry giants to specialized providers. When considering an investment in servo technology, identifying reputable manufacturers is crucial for ensuring quality, reliability, and long-term support.

Leading manufacturers in the servo press domain include:

Aida S.r.l.: A prominent name in the industry, Aida is frequently referenced for its advanced servo press technology, such as the Aida DSF-N2-3000 ServoFormer.5 Their articles provide extensive information on the cost, ROI, productivity, and tooling life benefits of servo presses.

Eagle Press: Recognized as a leading North American manufacturer of servo presses, Eagle Press is known for its commitment to engineering excellence, visionary design, and innovation. Their High Torque Servo Press series features high torque/low RPM servomotors, a 100% energy management system, and ultra-high precision gears, contributing to increased part quality and die life.17 Eagle Press emphasizes custom-designed solutions to meet specific production needs and performance requirements, offering a wide range of capabilities and production capacities up to 3,500 metric tons.

Beckwood Press: Another notable manufacturer, Beckwood Press, is recognized for its servo-electric presses, which are highlighted for their improved part quality, easy maintenance due to fewer components, and significant energy savings.

Beyond these, the market includes numerous other manufacturers that contribute to the global and diverse landscape of servo press manufacturing :

AGME Automated Assembly Solutions

Anhui Zhongrui Machine Manufacturing Co., Ltd.

Balconi

Bliss - Bret

BMG

BTM Europe Blechverb. GmbH

DEKUMA Rubber and Plastic Technology

Dongguan Hongjin Test Instrument Co.,Ltd.

Dongguan Jianlong hydraulic machinery Co., LTD

ebu Umformtechnik GmbH

Fagor Arrasate S.Coop.

Fancort Industries, Incorporation

Feintool Technologie AG

G.P.A. ITALIANA

Groupe MEYER France

H&T ProduktionsTechnologie GmbH

HMTMACH Hidrometa

Hursan Hydraulic Press

Hyundai Heavy Industries-Robotics System

IEF-Werner GmbH

Janome Industrial Equipment

LAMMAS

MECCATRONIZZA AUTOMAZIONI

MSE TEKNOLOJİ LTD. ŞTİ.

Neotecman

Ningbo Goanwin Machinery Manufacturing Co.,Ltd

Otto Bihler Maschinenfabrik GmbH & Co. KG

OZMACHINE

PROMESS Montage- und Prüfsysteme GmbH

SCHMIDT Technology

SCHULER - MÜLLER WEINGARTEN

SEYI HQ

Shenzhen Xintaiming Intelligent Equipment CO., Ltd.

SIGMA PRESSE S.r.l.

Simpac Europe GmbH

Sucorema, Lda

Suzhou Fengda Automoation Equipment Co., Ltd

SXKH GLOBAL

Yangli Group Co., Ltd.

Zhengxi Hydraulic

This extensive list underscores that the market for servo presses is not monolithic; it is geographically dispersed and comprises a mix of large, established players and smaller, specialized manufacturers. This diversity implies that buyers have a wide range of options, from high-tonnage industrial giants to niche providers for specific applications. It also suggests varying levels of technological maturity, after-sales support, and regional presence, all of which are critical considerations for a buyer beyond just the machine's technical specifications. When evaluating manufacturers, it is advisable to consider their geographical support network, industry reputation, and specific application expertise.

Conclusion

Servo presses represent a transformative leap in metalforming technology, offering unparalleled precision, significant energy efficiency, extended tooling life, and enhanced productivity. As a "third-generation" press technology, they move beyond the fixed mechanics of traditional presses to embrace programmable, adaptive manufacturing. Their ability to precisely control force, stroke, and speed, coupled with features like pendulum mode and in-die operations, enables the forming of complex parts from challenging materials with superior quality and reduced waste.

The comparison with mechanical presses highlights a clear strategic divergence. While mechanical presses offer a lower initial investment and are well-suited for high-speed, repetitive blanking and piercing, their fixed operational characteristics limit adaptability and efficiency for modern, complex applications. Servo presses, despite their higher upfront cost, deliver substantial long-term return on investment through significant energy savings, reduced scrap and downtime, extended tool life, and the ability to consolidate die stations and secondary operations. This makes them a compelling choice for manufacturers seeking to optimize operational costs and enhance product quality.

A critical aspect of maximizing the benefits of servo presses lies beyond the machinery itself. The inherent flexibility and advanced capabilities of servo technology necessitate a corresponding investment in human capital. Continuous training for engineers and operators, along with the strategic appointment of a "servo champion" dedicated to optimizing press performance, are crucial for unlocking the full potential and ensuring sustained ROI over the equipment's lifespan. Without this commitment to ongoing learning and process refinement, the advantages of a servo press may not be fully realized.

Looking ahead, the trajectory of press technology points towards even greater integration with Industry 4.0 principles, artificial intelligence, and advanced automation. Servo presses are ideally positioned to leverage these advancements, paving the way for further enhancements in efficiency, predictive maintenance, and intelligent manufacturing processes. The strategic decision to invest in servo technology is not merely an equipment purchase; it is a commitment to future-proofing manufacturing operations and securing a competitive edge in an evolving industrial landscape.

Emrah Demirezen

Metal Forming Expert & Press Designer

Comments