Understanding Torque Calculation for Clutch Selection in Mechanical Press

- Emrah Demirezen

- Nov 22, 2024

- 2 min read

Mechanical presses are extensively utilized across various industries for metal forming processes, including stamping, punching, and forging. The clutch system within a mechanical press is vital for transmitting power from the flywheel to the crank-slider or knuckle-joint mechanism, thereby regulating the press's operation. Choosing the appropriate clutch for a mechanical press necessitates a thorough evaluation of torque requirements to guarantee efficient and dependable performance. This article delves into the essential aspects of torque calculation for selecting a mechanical press clutch.

DEFINITIONS

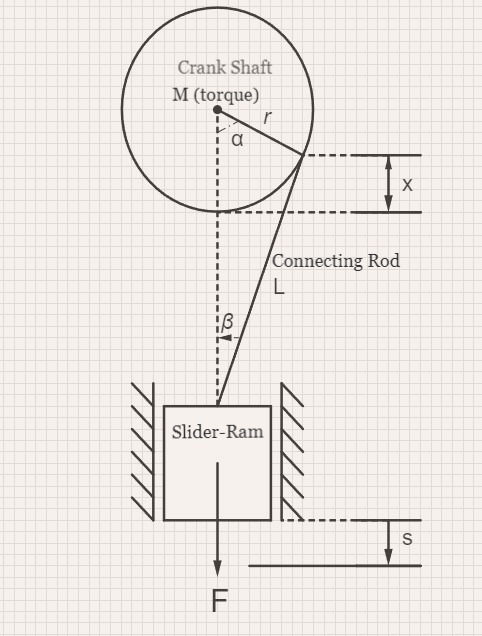

M (Transmission of torque by the crankshaft)

F (Rated press tonnage)

L (Length of connecting rod)

r (Eccentricity of the crankshaft or stroke/2)

ß (Angle between the connecting rod and the movement direction of the ram at the rated distance of the press)

α (Crankshaft angle)

s (Rated distance)

x (Distance of the connection point of crankshaft and connecting rod to BDC at the rated distance)

For further information on rated distance and the analysis of eccentric press mechanisms, please refer to our article.

Proceeding step by step:

Consider applying F (rated force over the distance s).

The force components on the ram will be F and Fguide, which represents the guide reaction. This is given by Fguide = F tan(ß).

Thus, there are two forces acting between the crankshaft and the connecting rod: F and Fguide.

To determine M (torque), use the formula: M = F r sin(α) + Fguide r cos(α), where:

M(torque) = F r sin(α) + F tan(ß) r cos(α), recalling the angle sum formulas from high school mathematics.

M(torque) = F r sin(α + ß) / cos(ß).

Let i represent the reduction ratio of the press gear system.

To ensure sufficient force is supplied to the ram without slipping,

Mclutch = M(torque) * i.

Finally, to select the appropriate clutch based on the torque requirement, we can refer to the catalogues of clutch manufacturers, ensuring that Mcatalogue > Mclutch.

Conclusion

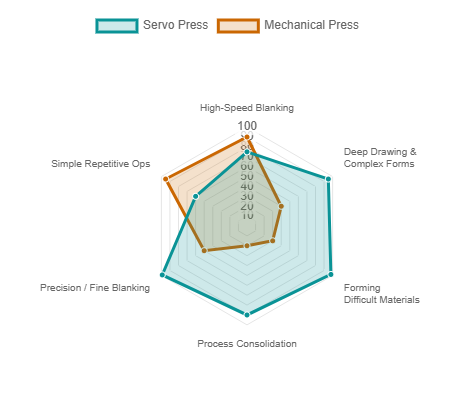

Selecting the appropriate clutch capacity is crucial for both manufacturers and stamping companies. High-capacity torque clutches than required can lead to dimensional challenges, as they occupy significant space, complicate the press crown design, make maintenance activities more difficult, and can damage the drive system in the event of an overload.

Low-capacity torque clutches can result in insufficient force transfer, clutch slippage, the need for calibration, and accelerated wear of friction plates, leading to increased maintenance frequency.

Selecting the appropriate clutch is crucial for effectively transmitting the necessary force, reducing the frequency of maintenance, and protecting the crankshaft, connecting rod, gears, and other components from overload damage.

You may refer to our previous article on clutches here. To stay informed about the online courses and training on related topics, please remember to subscribe and feel free to contact me with any inquiries.

Emrah Demirezen

Metal Forming Specialist - Press Designer

Comments